Enhanced Performance for Bakery Industry - uni 253 & 255

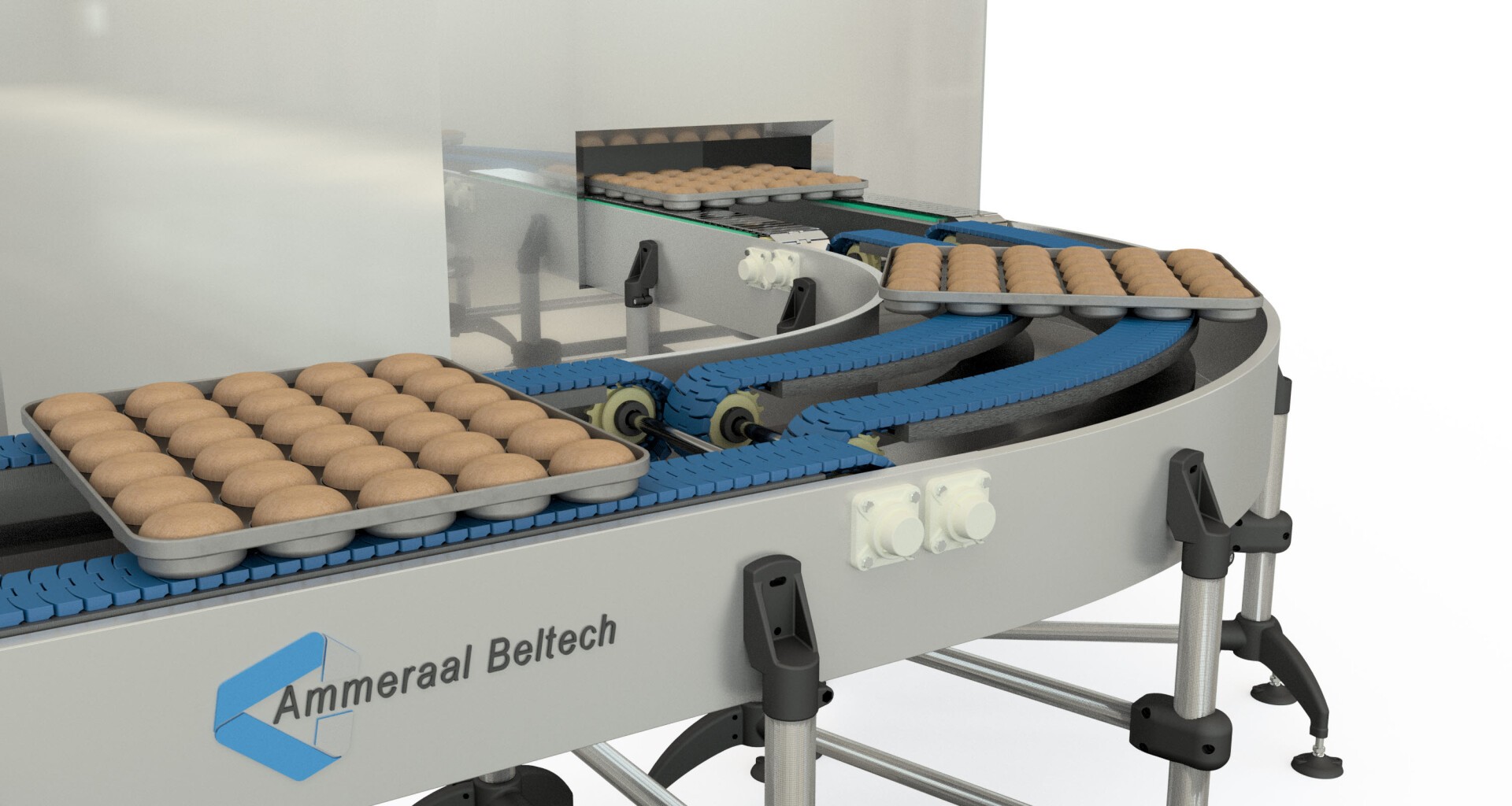

We proudly present the uni 253 and 255 side-flexing modular plastic chains — precision-engineered to serve the bakery industry. These chains are designed to overcome common operational challenges such as cooling deformation and stability issues, while ensuring smoother and safer conveying.

Designed for stability and performance

Both chain types offer enhanced lateral support and top-flight flatness, resulting in smoother product transitions and minimized pulsation or breakage. This ensures greater safety, less downtime, and consistent product flow — even in demanding applications like heated pan transport.

Technical features at a glance

Here’s what sets the uni 253 and 255 apart:

-

Pitch: 25.4 mm (1")

-

Thickness: 8.7 mm for uni 253; 12.7 mm for uni 255

-

Top Surface: Flush Grid or Flat Top (uni 253); Flat Top (uni 255)

-

Compatibility: Standard 880 / 879 / 881 conveyor tracks

-

Hinge Options: Bevel, TAB, and Magnetic (uni 253); TAB and Magnetic (uni 255)

Material options for demanding environments

These chains are available in several specialized food-grade materials, including POM D, PA6, PA6.6-GFH, and POM-DK — each offering varying strengths in wear resistance, heat stability, and friction reduction under dry or abrasive conditions. The default pin material is stainless steel for long-lasting durability.

Reliable. Efficient. Future-Ready.

Whether you're managing pan handling, or heated product lines, the uni 253 and 255 chains deliver superior wear resistance, product safety, and reduced total cost of ownership for bakery operations.