Bartech Spirona Spiral Systems – Flexible Design. Solid Build. Maximum Output in Minimum Space

Bartech Spirona Spiral Systems help you save space, increase production, and keep quality high. With flexible design and strong construction, they fit perfectly into modern food lines. Get more output with less space — reliably and efficiently.

At Bartech, we understand that modern bakeries and food production lines need more than just equipment — they need space-efficient, high-performance systems built to last. That’s why we developed Spirona, our advanced spiral system series engineered for flexibility, durability, and maximum productivity.

At Bartech, we understand that modern bakeries and food production lines need more than just equipment — they need space-efficient, high-performance systems built to last. That’s why we developed Spirona, our advanced spiral system series engineered for flexibility, durability, and maximum productivity.

With a modular, multi-tiered design, Bartech Spirona adapts easily to different production layouts — even in the most compact spaces. Its sturdy stainless steel structure ensures long-term operation under high-capacity demands, while delivering consistent product flow and quality.

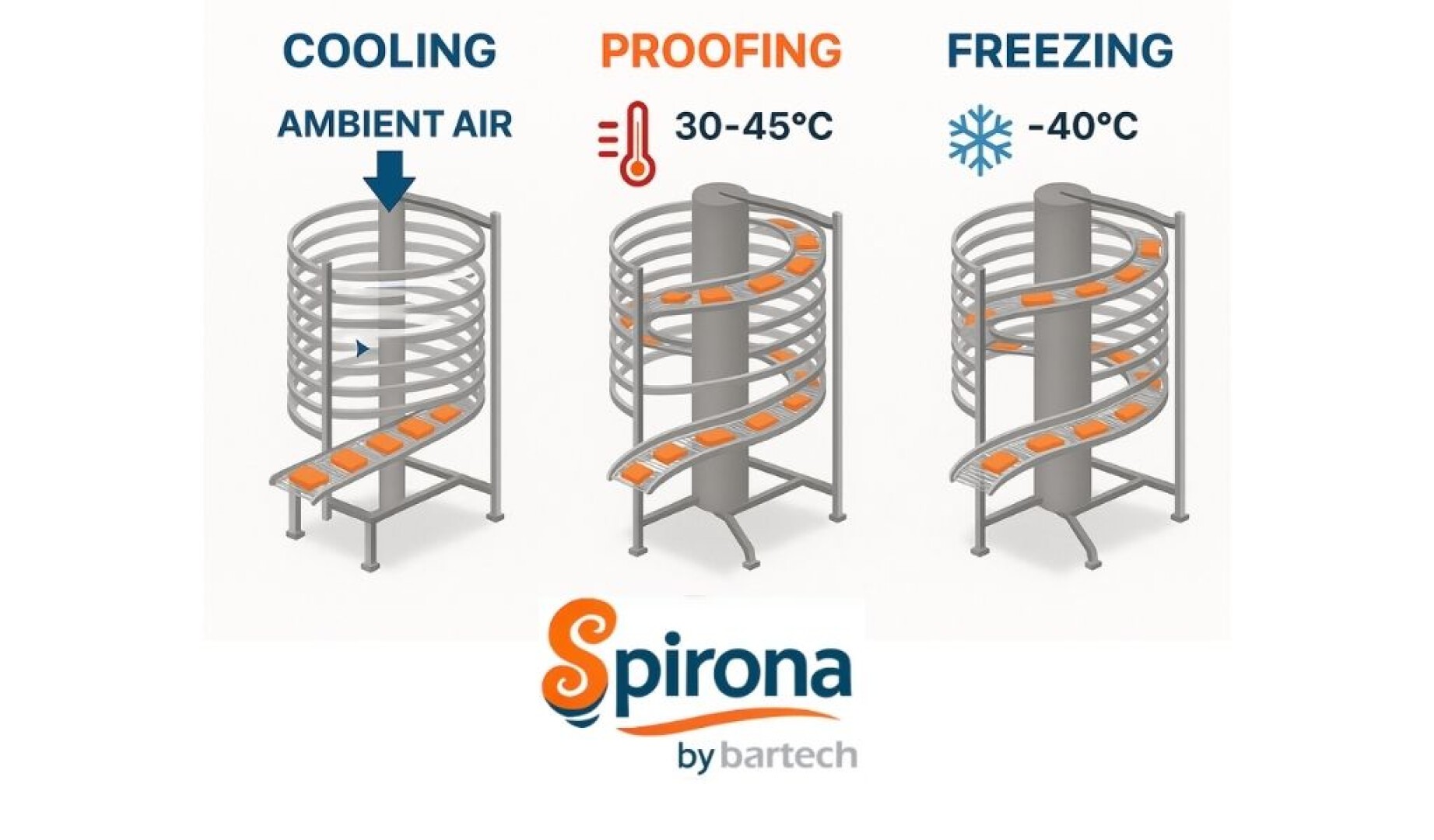

Whether for cooling, proofing, freezing, or conveying, Spirona spiral systems help you stack time vertically, reduce your footprint, and boost output — all in one smart, space-saving solution.

Built with high-quality stainless steel and industrial-grade components, the systems are engineered to perform reliably under continuous operation. Their modular design also provides flexibility for custom configurations, making them ideal for both new installations and retrofitting existing lines.

If you're looking to maximize your production capacity while using the least amount of space — all without compromising on strength or efficiency — our spiral solutions are the answer.

Visit us at Hall 11 D11 and see how we help bakeries and food manufacturers produce more, smarter.